Windsand

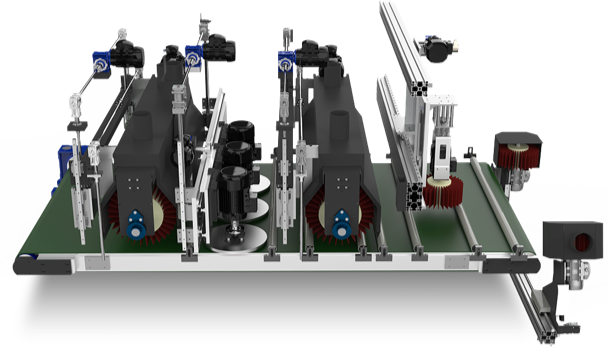

C.N.C. finishing center, the Windsand sanding machines are used for sanding and denibbing of window sashes and frames, doors and panels generally. This machine line is the guaranty to obtain the best surface quality through high performance equipment.

All sides are sanded through a dedicated aggregate thanks to our patented technology developed through decencies of experience.

- Steel structure ensures stability and strength

- Ground working tables maintain parallelism with sanding disks

- All adjustments of the operating units are on ball bearing linear guides to ensure long life, accuracy and high strength

- Powered feed belts for the work-piece movement, feed speed driven by inverter

- Pressure rollers all along the working process to ensure work-piece’s stability

- Pressure rollers coated with vulcanized rubber and provided with spring-loaded suspension

- All working units provided with dust extraction

- Cabin closes on six sides

- Side doors provided with safety system, machine stops in case of door opening. Doors have windows to allow the control of the work-piece

- Steel side reference guide of right hand machine entrance (zero reference)

Working procedure

Working cycle

Choice of pre-set working program.

Working and pressure units adjust automatically according to the selected program and the parameters entered.

The working cycle starts by setting work speed, the pressure of the units and rotating speed according to the selected program.

Machine configuration

All working units are driven by Inverter.

All brushes and sanding disks are provided with individually replaceable abrasive strips or sandpaper.

Thanks to the innovative Ecoline operating system, all working units ensure the maintenance of the work-piece geometry

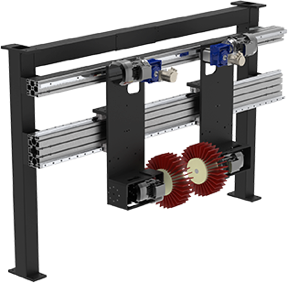

Nr.2 350 mm dia. vertical brushes, 0,55 kw motor each, variable rotating speed driven by inverter. Variable inclination 0°-35°. Horizontal stroke adjustment on linear guides.

350 mm dia. vertical brush for sanding work-piece head and inside of the window. kW 0,55 electronically controlled variable rotating speed by inverter.

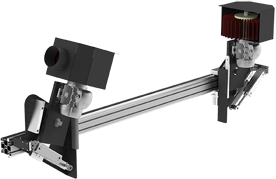

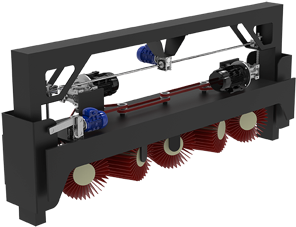

Nr 1 transversal brushes 320 mm dia. Kw 1,5.

Electronically controlled variable rotating speed by inverter. Vertical stroke 100 mm on linear guides and positioning control by reader.

Easier horiziontal extraction for abrasive strips change

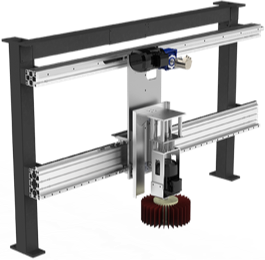

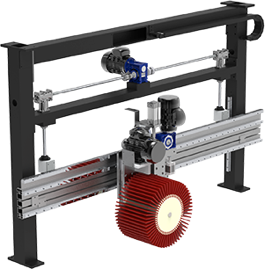

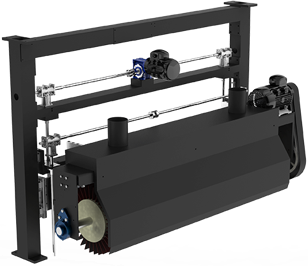

Nr 1 horizontal brush Ø 420 mm dia. cylindrical brush driven by 1.5 kw motor, electronically controlled variable rotating speed by inverter.

Vertical stroke 160 mm on linear guides, electronic adjustment according to work-piece thickness.

Easier horiziontal extraction for abrasive strips change.

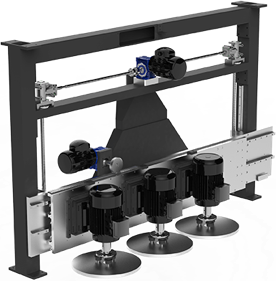

Nr. 3 420 mm dia. sanding disks driven by 1.5 kw motor each, electronically controlled variable rotating speed by inverter. Easier horiziontal extraction for abrasive change.

Unit consisting of 2 indipendent brushes 350 mm dia. Kw 0,75 each. Horizontal movement on linear guides and 2 vertical position 20-40mm. Electronically controlled variable rotating speed by inverter.

Unit composed by 5 cylindrical brushes Ø 320 mm with vertical and orizontal independent rotation. particularly indicated for milled surfaces or internal parts of the work-piece.

Accessories

- Out feeding table

- Orizontal brush motor power kw 7,5

- Cub brush

- Extra set abrasive paper

- Tynex brush brushes

- Still brushes

HMI

Full PLC control.

Choice of programs and settings through colour touch screen. Wide memory capability to save pre-set programs.

External USB support to export programs.

Large and understandable icons for easy and friendly use. Automatic control of abrasive workload and replacement. Remote after-sale service. (need of Internet connection).

| WINDSAND 2 | WINDSAND 3 | WINDSAND 4 | WINDSAND 5 | |

|---|---|---|---|---|

| Codes / groups | EC 56-000 EC 66-000 |

AL 156-000 | AL 135-600 AL 168-500 |

AL 135-460 AL 157-460 |

| Dimensions (length x width x height) mm | 2900x2300x2200 | 2900x2300x2300 | 2900x2300x2300 | 3900x2300x2300 |

| Working table height mm | 875 | 875 | 875 | 875 |

| Weight kg | 4000 | 4500 | 4000 | 4500 |

| Operating voltage | 400v | 400v | 400v | 400v |

| Electric current | 63a | 63a | 63a | 63a |

| Electric power Kw | 11 | 11 | 11 | 11 |

| Frequency Hz | 50 | 50 | 50 | 50 |

| Electrical cabinet protection | IP 55 | IP 55 | IP 55 | IP 55 |

| Air connection bar | 6 | 6 | 6 | 6 |

| Dust extraction mm | Nr 4 x Ø 120 | Nr 6 x Ø 120 | Nr 6 x Ø 120 | Nr 6 x Ø 120 |

| Workpiece dimensions | ||||

| Shortes piece mm | 550 | 550 | 550 | 550 |

| Max. width mm | 1550 | 1550 | 1550 | 1550 |

| Min. thickness mm | 10 | 10 | 10 | 10 |

| Max. thickness mm | 120 | 120 | 120 | 120 |

| Equipment | ||||

| Certification | ce | ce | ce | ce |

| hmi | Touch screen 11 inch | Touch screen 11 inch | Touch screen 11 inch | Touch screen 11 inch |

- 1 vertical brushes

- 3 central brush

- 4 transversal brushes

- 5 horizontal brush

- 6 sanding disks

- 7 doors unit

- 8 cups

- 9 3D Unit